Day 3 in Panama City got off to an early start as the GLCM group hopped on the bus to visit the Panama Metro. This rapid transit system is the first of its kind in Central America, and currently consists of two lines that link the southern and eastern outskirts of Panama City to the city center. Construction on Line 1 began in 2010, taking 4 years and $1.8B USD to construct before being inaugurated in the spring of 2014. Construction of Line 2 began just a few months later, requiring 3 years and another $1.8B USD to complete. With the success of the first two lines, plans have been made to expand the Panama Metro to a total of 10 lines by 2040, which will all operate within the greater Panama City area. The expansion, which will feature a 3-mile subway tunnel running underneath the Panama Canal, will consist of 5 metro lines, 3 tram lines, a metro-cable system, and a monorail.

We began our tour of the metro at Line 1’s first station, which is located at Albrook Mall. With Albrook being the 2nd largest mall in the Eastern Hemisphere, this station is one of the largest and busiest on the Panama Metro. The station was built with broad corridors and several escalators and stairs at each level change to account for the massive volume of passengers that pass through the station each day. As we traveled along the line, each station appeared to be designed to maximize natural lighting and corridor space to limit the sense of congestion for patrons. We traveled along most of Line 1 before switching to Line 2, which we rode to the very last stop.

As we traveled along, we learned that the Panama Metro serves over 30,000 people per hour, a substantial figure when considering the population of Panama City itself is only 470,000. Luis explained that prior to the completion of the Panama Metro, many people spent hours in traffic each morning as they commuted to their place of work by bus. The construction of Lines 1 and 2 has greatly reduced traffic on the major highways that run through the city and has cut down the time spent commuting to and from work for the tens of thousands of people living outside the city center. After reaching the end of Line 2, our group headed back towards the city center to jump back on the bus for our second excursion of the day.

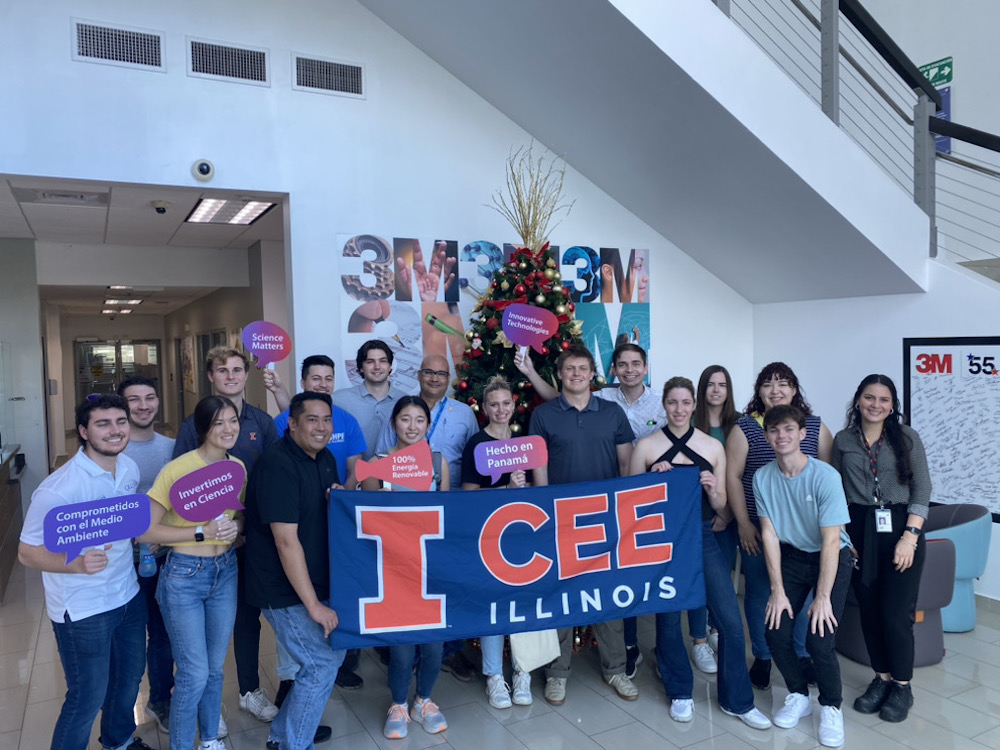

Our second activity of the day consisted of a visit to 3M’s Panama Pacific manufacturing and distribution facility. A team of facility managers and engineers welcomed us, providing a presentation outlining 3M’s manufacturing philosophy and operations strategy. We learned that as a company they follow 6 Sigma Lean philosophy, which places an emphasis on maximizing efficiency by reducing waste, time, cost, material and labor. All manufacturing employees are encouraged and empowered to continuously make recommendations for how their processes, equipment, and product can be improved. This strategy allows 3M to run an incredibly lean and efficient manufacturing operation.

Following the presentation, our group was taken on a tour of the manufacturing floor to see this philosophy in practice. The Panama Pacific facility produces a variety of products including polishing pads, abrasive pads, knifeless tape, and reusable plastic paint cannisters. Each product line was contained within its own section within the facility, each with a productivity board displaying the target production rates, actual production rates, and notes outlining issues that arose during the shift. Additionally, each product line had a dedicated board to display recommended adjustments, recorded anomalies, and past lessons learned. This system enables facility operators and managers to maintain the lofty standards for efficiency and innovation that characterize 3M’s company philosophy.

Blog by Jack Ambrosino