Canadian National Railway (CN) – Edmonton Office

We started the day with a hot breakfast from the hotel. Afterward, we arrived, with excitement, toward the CN Edmonton office, which is located right beside their second largest train yard, Walker yard.

Nigel Peters, who is the assistant chief engineer, started our visit with a brief overview of CN. Next was Tom Bourgonje, the regional chief engineer of the western region, who gave us an overview of the track construction within CN. He introduced us to some track projects in addition to detecting machines such as wayside detection (hot box/hot wheel detection system) which operates as an immediate hazard detector. These detectors give dispatchers an indication as to whether the wheels are overheating to a dangerous level due to friction or other sources and would then relay the information to the train operator who would inspect the issue. According to CN, this technology has been very effective in detecting defects in trains’ wheels.

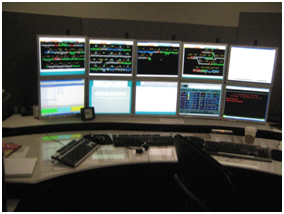

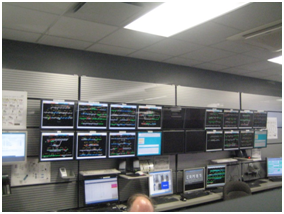

Jim Lowe presented next on the Second Narrows Bridge and its electrical system upgrade. The bridge was built in 1967 with the generators located in a tower above the bridge. The new electrical system turned out to be about half the size of the old system. This upgrade led to a discussion of other bridges that CN owned and operated and that were in need of upgrades, structurally and electrically, and when they were going to be implemented. Following the discussion we were given a tour of the dispatch center and were even given the pleasure of seeing/listening in on real time calls being placed to dispatchers. CN also explained and showed us how the different routes were monitored and controlled through the dispatch center.

After lunch, which was given to us by CN, we were greeted by Jim McLeod, the chief engineer for design and construction. He discussed projects that were happening stateside, including the acquisition of the EJ&E line that loops around the Chicagoland area and includes the Kirk Yard, located in Gary, IN. We picked up our discussion from earlier about bridge upgrades and also potential upgrades for the Kirk Yard and EJ&E line. Following the open discussion we said our thanks and parted ways to meet with Jacobs Engineering.

Jacobs Engineering – Edmonton Field Service Facilities

After arriving at the Edmonton Field Service Facilities at Jacobs Engineering, we started with a presentation given by Dave Postel with an overview of their Edmonton Field Service Facilities. This is a facility that provides all the module assembly, fabrication of the module, in-house equipment and tool rental in additional of managing the projects and personnel supports for their projects. Their average size of module is 24’ x 24’ x 120’. In the past few years, they have built up modules that were sent up to Fort McMurray for the Suncor project.

After the brief presentation, we went out and toured around the module fabrication yard with Jay Grant. It was very interesting by looking at how the different piping systems were being welded, grinded and put into place in an assembly line. The most exciting thing of this tour was that we all even gotten a chance to experience a close up look at the pipe welding task. We were certainly amazed with the fact that the workers were doing a fabulous job since all you could see through the welders’ facial mask was a green spot.

After the tour, Brent (mechanical supervisor) gave us another presentation about the steps that the Edmonton Field Service Facilities take from building up their modules to sending up to their dedicated destination. In addition, he also answered a lot of our questions that we had for our Kearl Oil Sand Project up in Fort McMurray. By then, we were definitely excited for our trip up to Fort McMurray.

Overall today was exciting. We definitely learn more about the Railroad Industry along with fabrication process of the modules for the Oil Sands project. We sure cannot wait till tomorrow to see the Edmonton Clinic that PCL Construction is working on.